Over the past several decades, the aerospace industry has been the impetus for the development of the high-nickel alloys we call Superalloys. When we think of heat resistance, coupled with corrosion resistance, creep strength, and toughness, we might at first think of austenitic stainless steels with high chromium and nickel contents and other alloy additions, but we eventually come to terms with the fact that service conditions in the various parts of the gas turbine engine warrant the use of high-nickel alloys.

Such an alloy is HX, commonly known by its trade name Hastelloy® X. This alloy contains nominally 47% nickel, 22% chromium, 2% cobalt, 18% iron, and 0.10% carbon. The alloy finds extensive use in gas-turbine engines for combustion-zone components such as transition ducts, combustor cans, spray bars and flame holders. It is also used in industrial furnace applications, where its resistance to oxidizing, neutral and carburizing atmospheres come into play. It finds further use in the chemical process industry for retorts, muffles and furnace baffles. It is also used in the nuclear engineering sector.

HX shows exceptional strength and oxidation resistance to 2200°F, and in fact exhibits good ductility after prolonged exposure at temperatures of 1200, 1400, 1600°F (650, 760, and 870°C) for 16,000 hours.

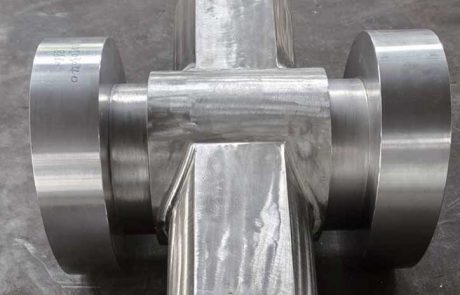

The basic chemistry of this alloy suggests caution in the melting and subsequent hot working processes. The alloy’s strength at high temperatures is such that it is not easy to hot work, and that cleanliness and soundness of the ingots are of prime importance. As such, the most stringent melting practices are in order here. Similarly with hot working, good temperature control is an absolute must. The forging temperature range, for example, should be 2150-2200 down to 1800°F, (1176-1224 down to 982°C) and it is mandatory that uniform heating to forging temperature occurs through the full section of an ingot. It is recommended that light, rapid blows be used until the cast structure is broken up – something that will be determined by experience – after which reasonably heavy blows may be used. The consensus seems to be that no forging should take place below 1800°F, (982°C) and that the alloy should not be subjected to a temperature above 2200°F (1204°F.)

Forged ingots are normally solution annealed at 2150/2175°F (1176/1190°C) to restore a uniform structure. Rapid cooling from this temperature is necessary.

Machining of this alloy is carried out in the solution annealed condition. Its machinability is 27% that of B1112 screw stock, hence slow speeds, positive feeds and rigid equipment are the order of the day. Sulfur-free lubricants should be used, along with carbide or high-speed steel tools.

Any cold forming of this alloy following initial hot work and solution annealing should be backed up by intermediate annealing during the forming process.

The alloy can be welded by metal arc, gas-tungsten-arc (T.I.G.), gas-metal-arc (M.I.G.), and submerged arc processes. Welded surfaces must be thoroughly descaled and cleaned. Pre-heating and post-weld heat treatments are not normally necessary. For the greatest corrosion resistance, however, solution-heat-treatment after welding may be necessary.

Alloy HX is not an easy material to work with. The melting and attendant primary processes must be such that inclusions and other internal defects are kept to a minimum to allow an efficient forging process. Careful attention to detail throughout the following processes is required.

AMFG has experience of the production of this alloy through the requisite processes and testing, to AMS 5754.